Products

Reversing gearbox for different crops harvesters

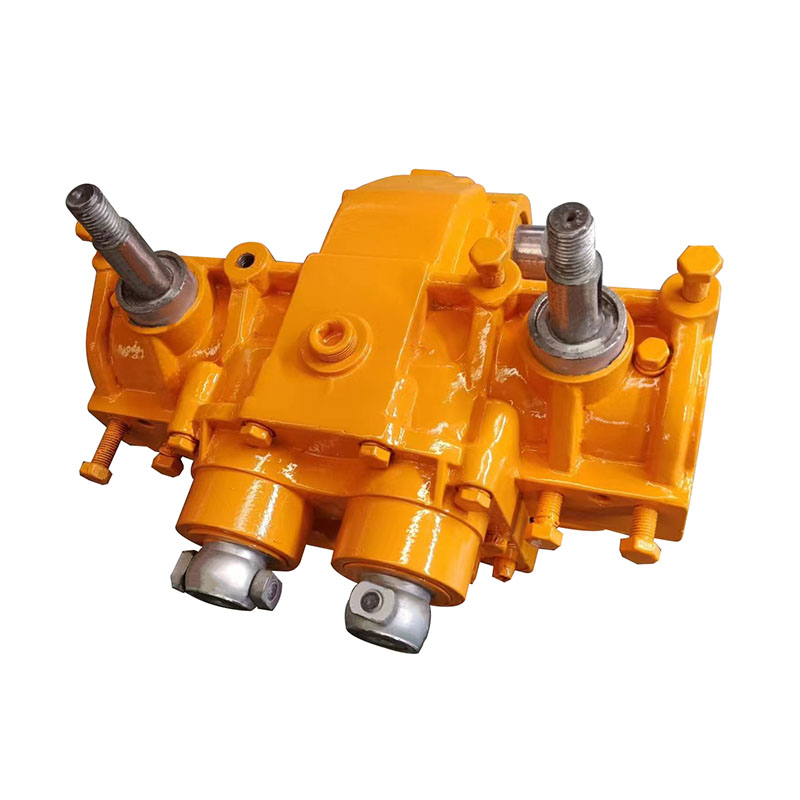

Baler Gearbox Assembly

Product Feature:

The box body of the baler assembly is made of high-quality ductile cast iron, which is a material that provides excellent strength and durability. This type of material ensures that the box body can withstand the high forces generated during the compressing process and maintain its structural integrity over time.

The compact structure of the baler assembly means that it can be easily integrated into different workflows and space constraints. Additionally, the sealed structure of the assembly helps to minimize the transmission of noise, making it suitable for use in noise-sensitive environments.

The connections used in the baler assembly are designed to be reliable and secure. This helps to ensure that the equipment can operate safely and effectively, reducing the risk of downtime or accidents. Furthermore, the installation of the equipment is straightforward and easy, allowing the assembly to be quickly set up and put into operation.

Overall, the combination of a ductile cast iron box body, a compact and sealed structure, and reliable connections makes the baler assembly a durable, efficient, and safe solution for compressing and packaging materials.

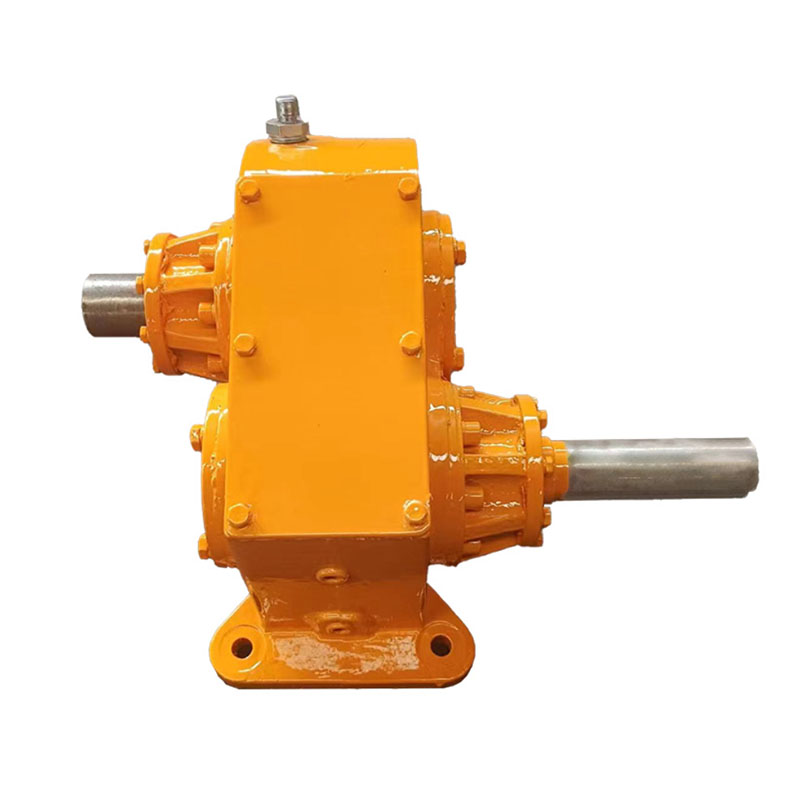

Conveyor Chute Gearbox Assembly

Product Introduction:

Matched model: Self-propelled harvester.

Speed ratio: 1:1.

Weight: 33kg.

External connection structure size can be customized.

Product Feature:

The conveyor gearbox assembly is designed to transmit power from the motor to the conveyor system in a smooth and efficient manner. To achieve this, the gearbox assembly is constructed with a box body that is highly rigid and has a compact design, making it durable and easy to integrate into the conveyor system.

The gearbox assembly utilizes large modulus straight spur gears, which are designed to provide a stable and efficient power transmission system. This type of gear meshing results in a smooth and quiet transmission, which is critical for conveyor systems that operate in noise-sensitive environments.

The connections on the gearbox assembly are designed to be reliable and easy to use, with a high level of versatility to allow for integration with different conveyor systems. This makes it an ideal choice for a wide range of industrial applications, including food processing, packaging, and materials handling, among others.

Installation of the gearbox assembly is made easy due to its compact design and simple assembly process. This ensures that the equipment can be installed quickly and without complications, allowing it to be put into operation in a timely manner.

Overall, the combination of a strong and rigid box body, large modulus straight spur gears, and reliable connections make the conveyor chute gearbox assembly a durable and efficient solution for a variety of industrial applications.

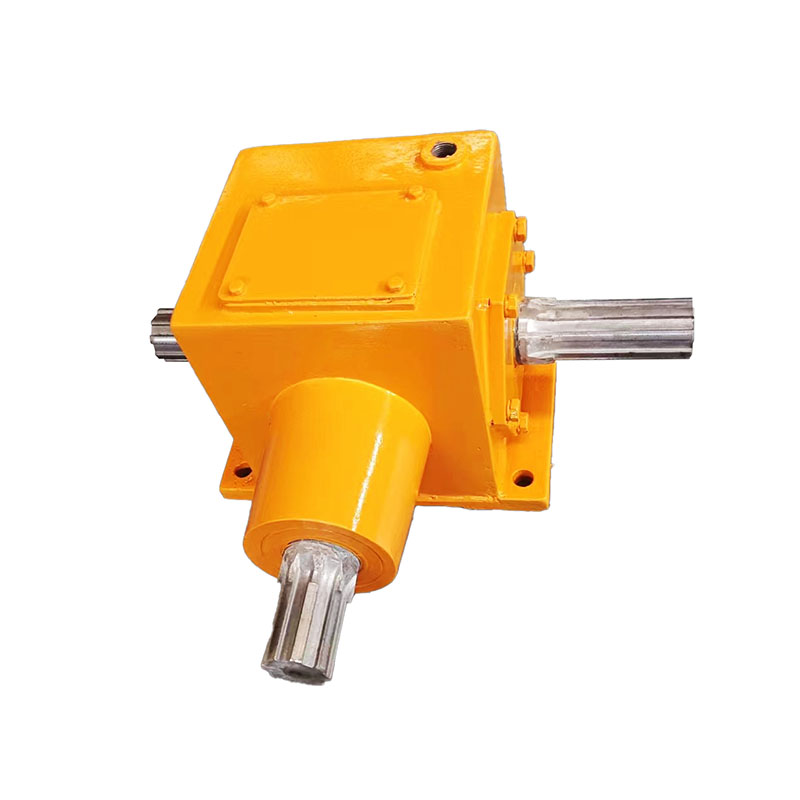

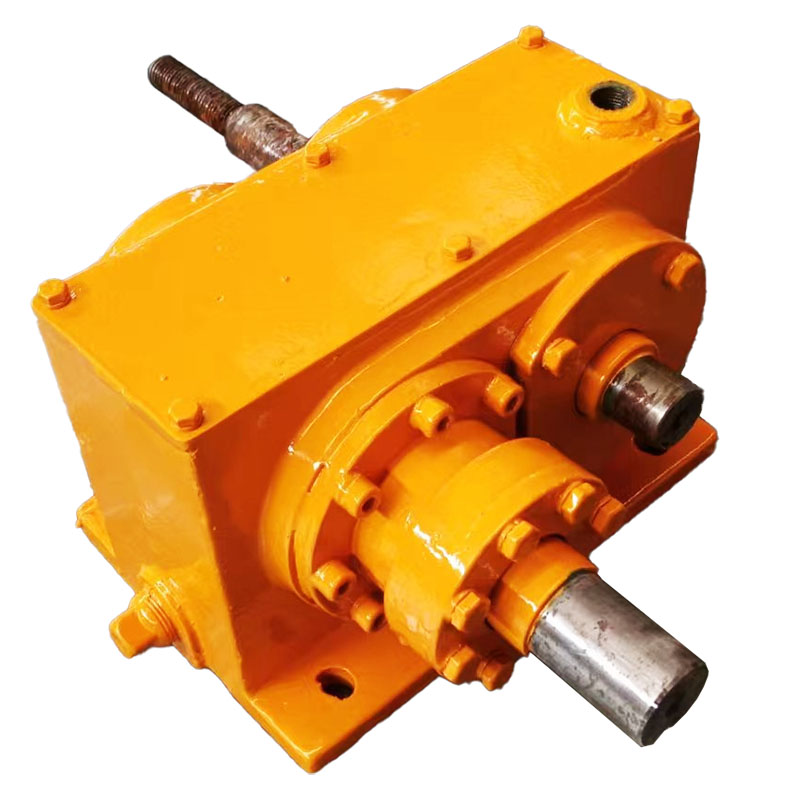

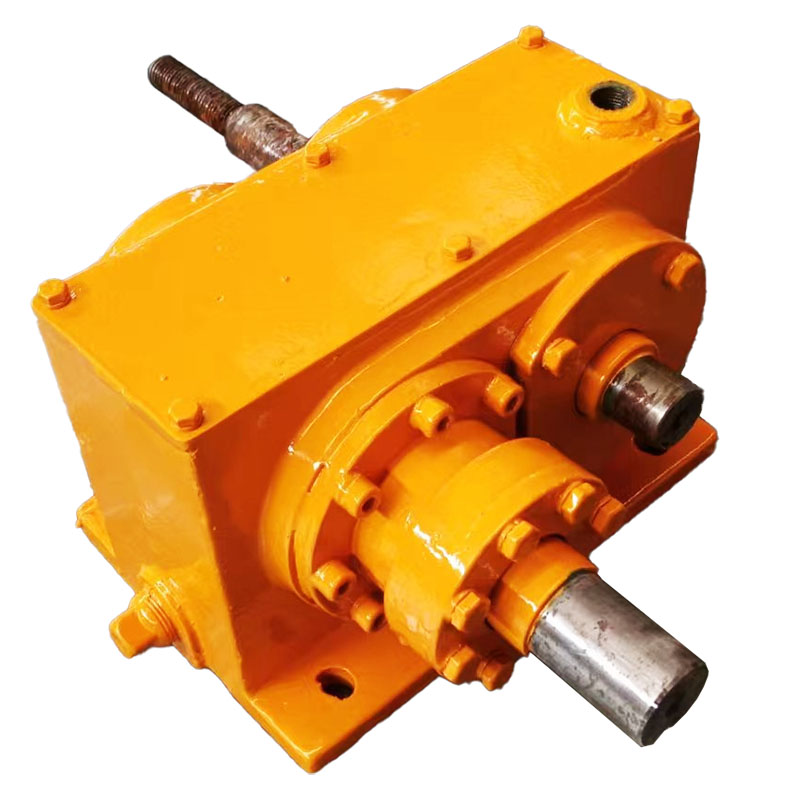

Header Reversing Gearbox Assembly

Product Introduction:

Matched model: Self-propelled corn harvester(3/4 rows).

Gear ratio: 1.33.

Weight: 27kg.

The external connecting structure size can be customized according to customer requirements.

The vehicle installation wheelbase can be customized according to user requirements, and a static hydraulic system can be used.

Product Feature:

The box body of this product is manufactured using high-quality ductile cast iron material, which provides a number of advantages. Firstly, ductile cast iron has high tensile strength, toughness and excellent wear resistance, which makes it extremely durable and long-lasting. Secondly, its compact structure makes it easy to transport and install, without taking up too much space.

Additionally, the box body adopts a closed structure which provides several benefits. The closed structure design ensures that the transmission is smooth and efficient, with low levels of transmission noise. This makes the product ideal for use in environments where noise levels need to be kept to a minimum.

Furthermore, the reliable connection ensures that all components are securely fastened, and minimizes the risk of loosening during operation. This ensures the safety of the user and reduces the likelihood of accidents occurring. Finally, the easy installation design of the box body makes it simple to install, which saves time and effort during the manufacturing process.

Want to discuss what we can do for you?

Explore where our solutions can take you.